The Marketer’s Guide to the Most Important Ratios to Manage in a Manufacturing Company

If you are a marketer who is looking for the most important ratios to manage in a manufacturing company, you […]

Read More »Become a successful marketing consultant: Learn more

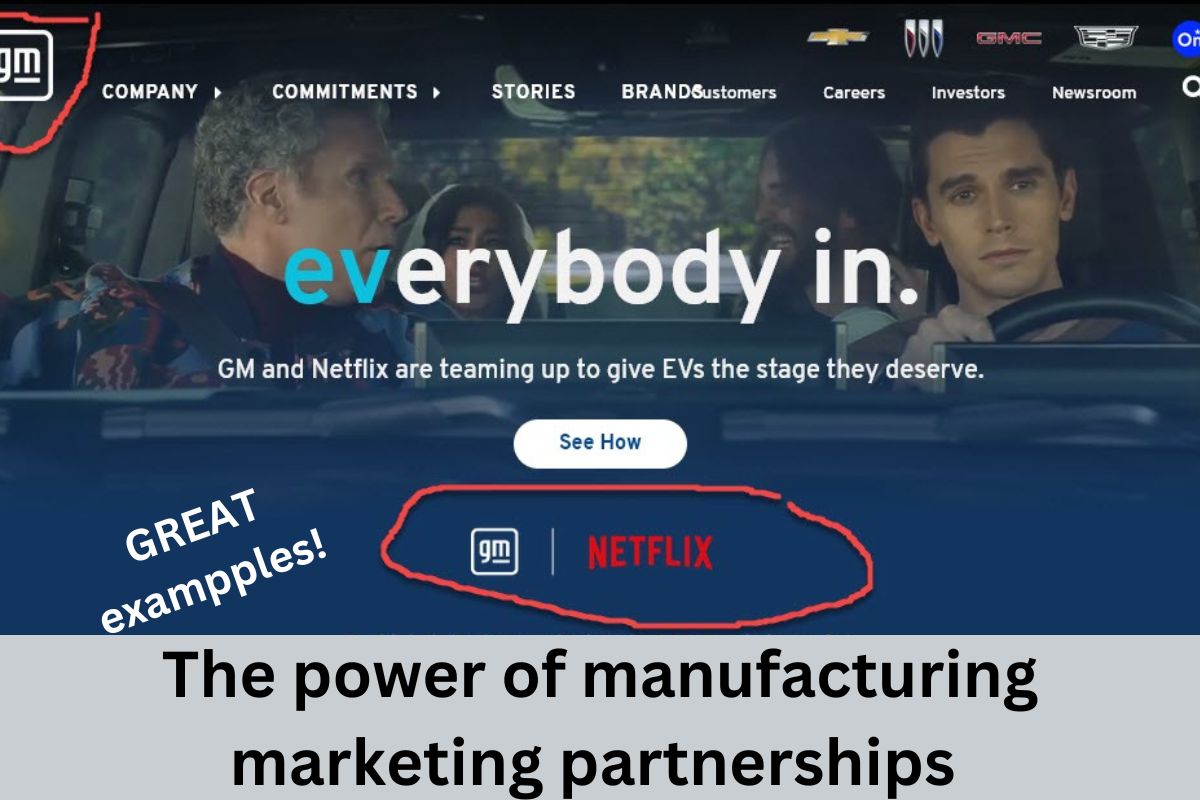

If you want to create a better product and achieve more growth through marketing and manufacturing partnerships. You have come to the right article.

In this article we walk through some famous examples and organize some simple steps for you to take your manufacturing business to a new level.

What is an example of manufacturing partnership?

The partnership between Toyota and GM is a great example. Toyota was able to learn about the U.S. auto market and access GM’s distribution networks. Alternatively, GM benefitted from Toyota’s expertise in lean manufacturing and quality control.

As we get ready to review this important topic, here are two very helpful articles that you will enjoy:

5 Market expansion strategies (+examples)

Growth Marketing: 4 Core Markets that Need to be in Your Strategy

Let’s now get into some details of a famous example of two companies partnering and gaining from the partnership, both in marketing and operations.

A manufacturing partnership is an arrangement between two or more companies to share resources, expertise or capital in order to achieve a common goal.

A well-known example of a manufacturing partnership is that between the Japanese automaker Toyota and the American automaker General Motors.

In 1984, the two firms entered into an agreement to collaborate on the development and production of vehicles.

Under the terms of the agreement, Toyota and GM would share the costs associated with manufacturing and marketing, as well as their respective technology and intellectual property.

In addition, the two companies agreed to share resources, technology, and engineering expertise.

The partnership between Toyota and GM has been beneficial to both companies.

Through their collaboration, Toyota was able to learn more about the U.S. automotive market and gain access to GM’s distribution networks and dealerships.

GM, on the other hand, has been able to benefit from Toyota’s expertise in lean manufacturing and quality control.

GM has used Toyota’s production processes to reduce the cost of production and increase the level of quality in its vehicles.

The partnership between Toyota and GM has been a successful one.

Since the partnership began, the two companies have produced several joint-venture vehicles, such as the Toyota Corolla and the GM Cavalier. In addition, Toyota has used GM’s manufacturing and marketing networks to launch its own vehicles in the U.S. market, such as the Toyota Camry.

The partnership between Toyota and GM has allowed both companies to capitalize on their respective strengths and resources, while minimizing their weaknesses and costs.

It has enabled both companies to become more competitive in the global automotive market and has allowed them to produce higher quality vehicles at a lower cost.

In conclusion, the partnership between Toyota and GM is a great example of how two companies can work together to achieve common goals and benefit from each other’s resources and expertise.

By sharing resources and technology, the two companies have been able to produce higher quality vehicles at a lower cost and become more competitive in the automotive market.

The partnership has been beneficial to both companies and has been a successful example of manufacturing partnership.

For more helpful articles about growth and gaining a competitive edge, visit this helpful resource:

A manufacturing partnership is a strategic alliance between two or more companies that agree to cooperate in the manufacturing process. The purpose of a manufacturing partnership is to leverage the combined resources of the partner companies in order to increase their efficiency, reduce costs, and improve product quality and customer service.

There are several benefits to a manufacturing partnership, including cost savings, quality assurance, and improved customer service.

Cost Savings: Manufacturing partnerships typically involve sharing resources to reduce costs. By pooling resources, partner companies can reduce overhead costs associated with production, while also benefiting from economies of scale related to purchasing materials, equipment, and labor. This, in turn, can reduce the cost of production, allowing partner companies to offer competitive pricing.

Quality Assurance: Quality assurance is important in any manufacturing process and is a key benefit of a manufacturing partnership. By sharing resources and expertise among partner companies, quality assurance can be improved. For example, partner companies can share quality control protocols to ensure that products meet a certain standard of quality.

Improved Customer Service: A manufacturing partnership can also improve customer service. By sharing resources and expertise, partner companies can better understand customer needs and develop products and services that meet those needs. This, in turn, can lead to improved customer satisfaction and loyalty.

Manufacturing partnerships typically involve two or more companies that have complementary resources, expertise, and capabilities. These companies can be of any size, from large corporations to small businesses.

Common types of companies that enter into manufacturing partnerships include:

Manufacturers: Manufacturers are the most common type of company to enter into a manufacturing partnership. These companies typically have the resources, expertise, and capabilities necessary to produce products. By partnering with other manufacturers, they can increase efficiency, reduce costs, and improve product quality and customer service.

Suppliers: Suppliers are another type of company that often enter into manufacturing partnerships. By partnering with manufacturers, suppliers can provide a steady supply of raw materials, components, and other resources necessary for the manufacturing process. This, in turn, can reduce costs and improve the efficiency of the production process.

Technology Companies: Technology companies are also common partners in manufacturing partnerships. By partnering with manufacturers, technology companies can provide the latest technology and expertise necessary to improve the efficiency and quality of the production process. This, in turn, can lead to cost savings and improved customer service.

There are numerous examples of successful manufacturing partnerships around the world.

Some of the most successful partnerships include:

General Motors and Honda: In 2020, General Motors and Honda announced a joint venture to develop a new electric vehicle platform. The partnership combines the technology and expertise of both companies to create a new vehicle that meets customer needs and is cost-effective to produce.

Toyota and Subaru: Toyota and Subaru have a long-standing partnership to produce vehicles together. The two companies have collaborated on several successful vehicle models, including the Toyota 86 and Subaru BRZ. The partnership has allowed both companies to leverage each other's resources, leading to cost savings and improved customer satisfaction.

Apple and Foxconn: Apple and Foxconn have a long-standing partnership to produce Apple's products. The partnership has allowed Apple to tap into Foxconn's manufacturing expertise and resources, leading to improved product quality and customer service. The partnership has also allowed Apple to remain competitive in the global market.